WIRTGEN picks and cutting tools

Increased productivity, reduced costs

Picks are a vital ingredient of the

WIRTGEN cutting technology. They remove the pavement in the milling

process, granulating it into small-sized, reusable material. The

different operating conditions and types of stress encountered on

construction sites both require and promote the development and ongoing

refinement of the picks.

Das Design der Rundschaftmeißel variiert

zwischen den unterschiedlichen Typen abhängig vom Einsatzgebiet bzw.

vom Anwendungsbereich. Die Komponenten und ihre Funktion sind jedoch

immer identisch.

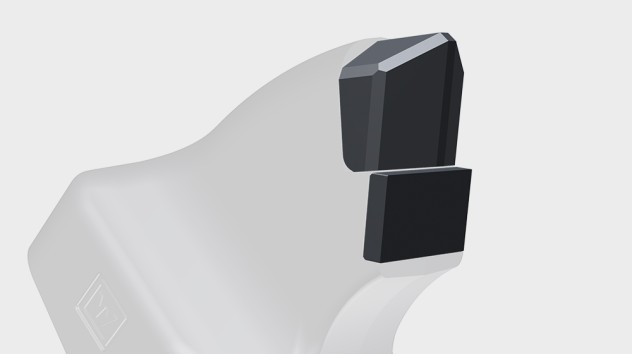

Cutting tools for milling machines

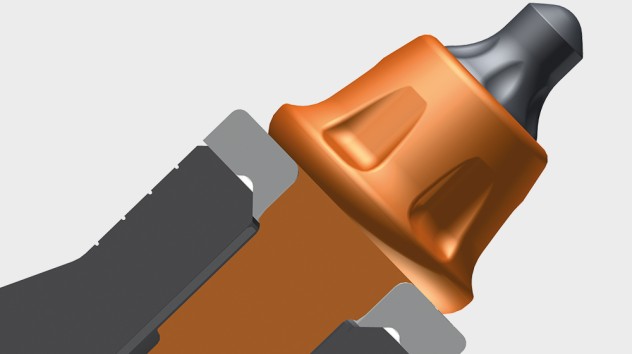

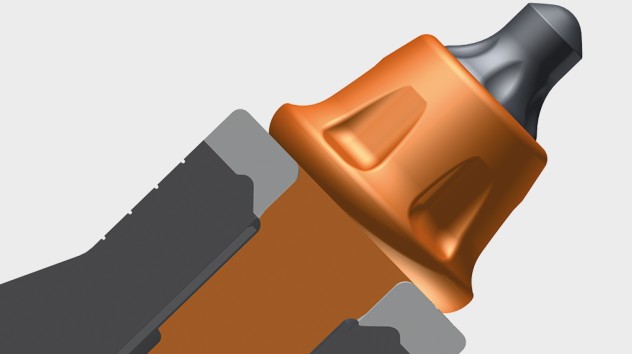

The GENERATION X² picks excel due to

unique product features, which, above all, reduce operating costs

significantly. Thanks to the newly developed wear plate with a special

groove profile, centring is improved and rotation performance

demonstrably optimised. This ensures that the carbide retains its high

cutting performance and guarantees optimum carbide utilisation. The

groove profile also reduces lengthwise wear in the pick toolholder and

increases service life by up to 25 %.

Highlights of GENERATION X² picks

GENERATION X²: Carbide is the most

economical solution as a cutting material for inhomogeneous materials

being milled with abrupt peak loads to be expected. The all-round

GENERATION X² carbide picks thus provide the optimum solution for every

application, no matter whether you need to handle hard or soft asphalt

or are milling concrete.

Self-stamping of the toolholder centring profile through use of the GENERATION X²

|

|

|

|

W6/20X² with flat pick contact surface at 0 h

|

W6/20X² with pronounced centring profile after < 50 h

|

Impressive

- Increased service life for upper part

of the toolholders by up to 25 % due to the unique groove profile on the

wear plate lower surface of the GENERATION X² picks

- Enormous versatility in the

well-conceived GENERATION X² pick product range for a whole variety of

construction-site-specific requirements

- High operational reliability for the

newly conceived, adapted carbide tip geometry to absorb maximum loads

and minimise risk of carbide breakage

PKD cutting tools

Specialist in surface course rehabilitation and (micro) fine milling

PCD milling tools are perfectly suitable

for surface course rehabilitations and (micro) fine milling

applications due to their tool geometry and materials. They feature a

highly wear-resistant tool tip made of polycrystalline diamond (PCD)

with an extremely long service life. The very slight lengthwise wear

ensures optimum evenness over the milled surface and consistently high

machine feed.

Depending on their application, PCD

milling tools are a useful addition to the existing pick range featuring

conventional carbide tips.

Highlights of PCD cutting tool

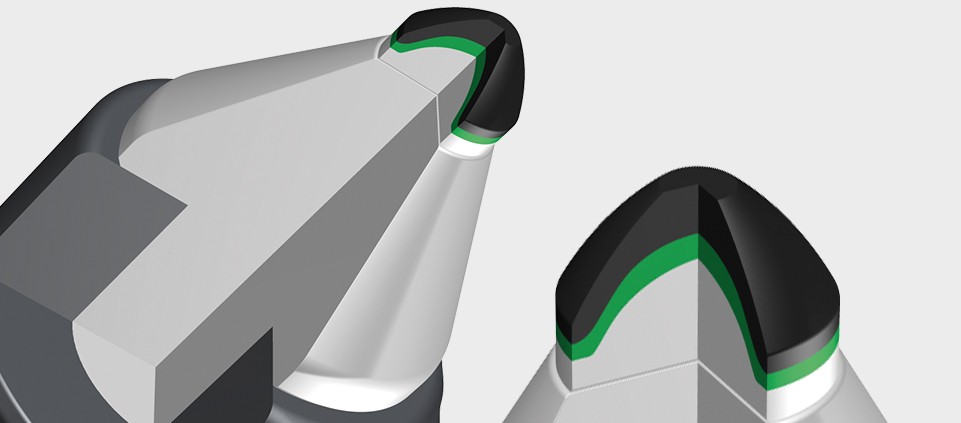

PCD milling tools: Polycrystalline diamond (PCD) is the optimal solution

as a cutting material for homogeneous asphalt packages, particularly

where no abrupt peak loads are expected. PCD milling tools are

particularly ideal as an economical alternative for surface course

rehabilitations up to 8 cm and for (micro) fine milling applications.

Schematic figure of a PCD tip

Impressive

- Constant milling pattern due to significantly reduced lengthwise wear

- Increased machine productivity thanks to fewer or no tool replacements and a consistently high machine feed

- Lower operating costs thanks to lower maintenance requirements

Cutting tools for cold recyclers and soil stabilizers

All-rounder for cold recycling and soil stabilization

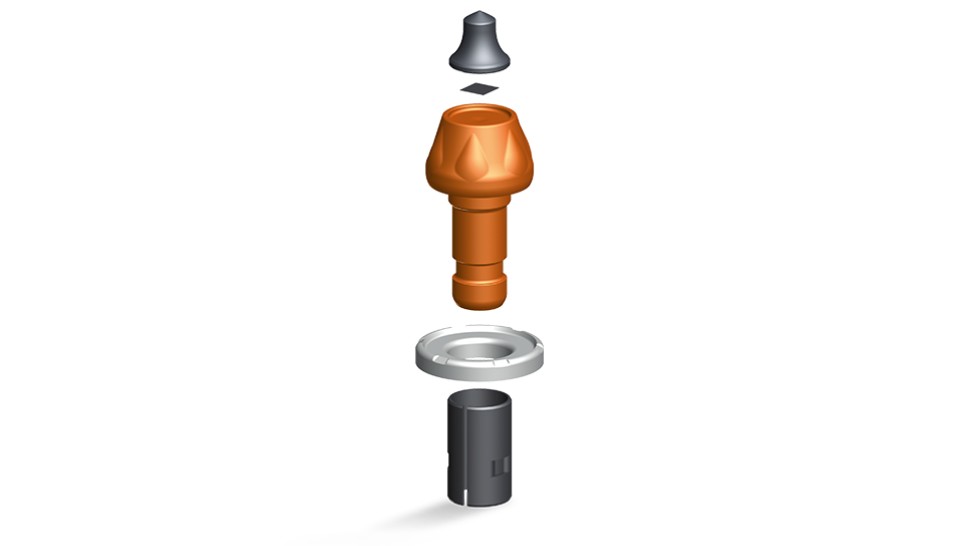

GENERATION Z picks

excel due to unique product features, which, most importantly, reduce

operating costs. Thanks to their adapted shank design and optimized

carbide tip geometry with a reinforced carbide base, the picks in this

product line are designed to withstand high impact loads and are thus

the ideal solution for recycling and stabilizing applications.

The relatively

large steel body volume compared to conventional picks and the

reinforced wear plate deliver the longest possible service life for

tools and optimum protection for the upper part of the toolholders in

applications involving abrasive materials.

Highlights of GENERATION Z picks

The

carbide mix with a high cobalt content of 7% and the reinforced carbide

base deliver high stability in the carbide, even under extremely high

impact loads. The GENERATION Z all-rounders thus offer the optimal

solution for all cold recycling and soil stabilizing applications.

Optimized carbide mix dimensionally correct for applications where high impact loads are expected.

Carbide tip on a conventional pick with a tungsten-cobalt mix of 94% to 6% Carbide base 1.25 mm thick

|

|

| Carbide tip on a conventional pick with a tungsten-cobalt mix of 94% to 6% Carbide base 1.25 mm thick |

Carbide tip on a GENERATION Z pick with a

tungsten-cobalt mix of 93% to 7% Carbide base 1.75 mm thick – 40%

thicker than in conventional picks |

Impressive

- High operational reliability thanks to exceptional impact stress resistance

- Greater productivity, particularly when mixing abrasive materials

- Maximum machine advance rate thanks to flow-optimized pick geometry

WCC milling tools

Specialist in stony ground

WCC (WIRTGEN COMPACT CARBIDE) milling

tools are eminently suitable for mixing compact soils with large pieces

of rock thanks to their tool geometry and materials. They feature a

highly wear-resistant carbide cutting edge, which is extremely

fracture-resistant and impact-proof.

Depending on their use, WCC milling tools make a useful addition to the existing pick range with conventional carbide tips.

igenschaften der Hartmetallspitzen: GENERATION Z und WCC Fräswerkzeug

|

|

| Carbide weight: 47 g |

Weight of carbide tip: 182 g

Weight of protective element: 47 g

Total carbide weight: 229 g |

Impressive

- Maximum machine productivity thanks to fewer or no tool exchanges

- Low operating costs thanks to lower maintenance requirements

- Maximum impact stress resistance even for large pieces of rock

Picks for Surface Miners

Hard-wearing picks for tough applications

Selecting the right pick is of vital

importance both for high cutting performance and for the service life of

the pick itself. The pick head diameter, pick head length, carbide

diameter and additional armouring are selected individually, based on

the material properties and rock hardness, in close cooperation between

the customer and WIRTGEN experts.

Different carbide geometries are also

used in surface mining due to different fields of application and

materials to be cut. Mushroom-shaped carbide tips protect the steel body

against erosion; cylindrical carbide tips are used in hard materials.

|

|

|

| Cylindrical tip, stepped shank diameter from 38 mm to 30 mm |

Cylindrical tip, shank diameter of 42 mm |

Cylindrical tip, shank diameter of 42 mm, armoured tool head |

Picks with 42-mm shank diameter are

usually fitted with short clamping sleeves and are used in HT14 and HT15

toolholder systems. These tools are installed in the holder using a

copper hammer. Clamping sleeves ensure a rapid, easy change of cutting

tools.

Công nghệ khác

WIRTGEN milling and cutting drums

WIRTGEN toolholder systems