WIRTGEN toolholder systems

WIRTGEN toolholder systems

Extended service life, higher machine availability. Maximum structural

integrity and wear resistance are vital qualities for the picks to

ensure highly precise and productive milling and cutting operations. The

picks are firmly anchored in the heavy-duty WIRTGEN toolholder systems

and can be replaced quickly and easily right on the construction site.

The consistent further development of our toolholder systems is always

based on the goal of improving the performance and efficiency of our

machines and offering reliable solutions to our customers.

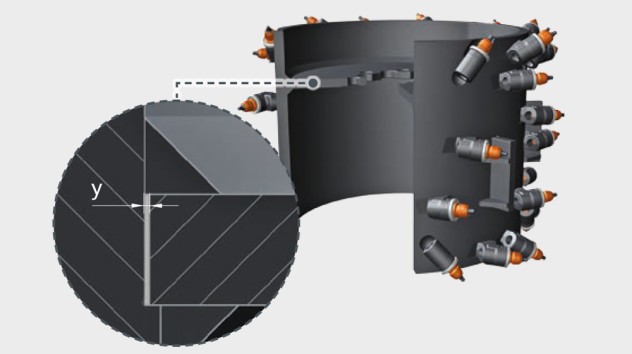

WIRTGEN welded toolholder HT08 for small milling machines

Reinforced toolholder system for reduced operating costs. With the HT08

toolholder system, the toolholders are permanently welded to the milling

drum. They are preferred for milling drums with small cutting circle

diameters. The efficient design and high strength materials increase the

lifespan of the toolholder.

The advantages of HT08 welded toolholder

|

- Intelligent material distribution increases the expected service life by up to 75 %.

- The design height of the toolholder ensures the use of an automatic pick

ejector at any condition of wear. It reduces the time needed for

changing the picks.

- The holder geometry enables low-wear integration of the welded seam

along the border of the milling drum throughout the entire useful life.

- Due to an adapted holder geometry and a corresponding milling pocket, an

ideal welding seam can be applied onto the milling drum tube.

- Reinforced positioning cylinders enable improved repositionability.

|

|

|

|

Improved runout and increased eveness of the milling pattern

The reduced tolerances (see

measure y) created by machining the inner wall of the drum tube and

fitting of the ornamental flange gives an improved runout milling drum.

|

Minimised wear of the edge ring

Intelligent positioning of

the edge ring toolholders substantially minimises the edge ring wear on

the milling drum when milling narrow radii.

|

WIRTGEN quick-change toolholder systems

Damaged or worn picks and toolholders should be replaced in order to

minimize operating costs. WIRTGEN quick-change toolholder systems allow

picks and toolholders to be replaced quickly and easily right on the

construction site. Quick-change toolholder systems primarily consist of

two parts: a housing (bottom part of the toolholder system) welded to

the milling drum tube, and a toolholder (upper part) connected to the

housing via a quick-release bolted connection.

WIRTGEN quick-change toolholder system HT22

Extended service life, higher machine

availability. The quick-change toolholder system HT22 is characterised

primarily by an increased wear resistance. The system’s especially long

service life makes itself apparent on the construction site by a

considerable reduction of the replacement intervals. A characteristic

feature is the prismatic arranged contact surface.

For the user, this directly results in

an extended service life of both the pick and the quick-change

toolholder system. The resulting advantages – fewer picks needing to be

replaced, less idle times, extended maintenance intervals and increased

machine uptime – allow even the most challenging soils to be stabilized

economically, and heavily damaged pavement structures to be milled off

and recycled in an efficient process.

Highlights of HT22 toolholder systems

Impressive

- Maximum possible impact load and also

shear load in extreme cases thanks to a reworked toolholder shank

geometry and optimised heat treatment.

- Fewer maintenance requirements since

the pressure screw in the HT22 quick-change toolholder system needs to

be re-tightened only every 500 machine operating hours.

- Better lower part protection thanks to

a greater wear volume in the shoulder section in the upper part of the

toolholder to ensure a longer service life for individual lower parts

and the entire milling drum.

WIRTGEN quick-change toolholder system HT15 for Surface Miners

Highly robust toolholders

Quick-change toolholder system for

rapid, easy exchange of upper toolholder parts. Created for high stress

loads and wear exposure in surface mining.

The advantages of HT15 quick-change toolholder system

|

- Specially heat-treated holder shank for increased strength

- Heavy-duty shank mounting for the use of WIRTGEN point-attack cutting tools

- Precise contact surfaces between upper part and bottom part for transfer of the cutting forces

- Double prism for optimal seating and supporting action of upper part in bottom part

- Material guides to protect the bottom part from abrasive wear

- Pronounced recesses in bottom part to protect internal threads and bolts from damage

- Large opening in upper part to ensure optimum access during tool replacement

- Solid mounting bolts and flexible silicone plugs to protect the fine thread from moisture and dirt

|

HT15 reduces the time required to

replace a single toolholder from 90 minutes to only 15 minutes compared

to conventional, welded toolholder systems.

Công nghệ khác

WIRTGEN milling and cutting drums

WIRTGEN picks and cutting tools