VOEGELE WITOS Paving

Amid growing cost pressures and demands for better pavement quality and a longer road service life, it is becoming increasingly important to exploit untapped potential for the paving process. This is where WITOS Paving comes into play. The VÖGELE solution for process optimization and documentation lays the basis for more effective planning, greater transparency and a targeted, more rapid response to disruptions in the main processes associated with asphalt paving.

All parties involved in the project are linked in a network. WITOS Paving connects the supervisors in the asphalt mixing plant, the logistics company’s lorry drivers and the entire paving team on site. The system provides planning engineers and site managers with a full overview of the current construction process. Disturbances and obstructions arising in the construction process are detected more rapidly, providing the persons in charge with a wide range of possibilities for intervening. They are put in a position where they can take immediate optimization measures and remedy deviations from the planned workflow in real time.

| What’s more, the projects can be analysed and documented with WITOS Paving after completion of the job site. The collected data are then available to optimize future projects. In this way, working with WITOS will, in the medium and long term, help to significantly boost the overall cost-efficiency of road construction projects. |

|

|

The highlights of WITOS Paving

- WITOS Paving facilitates project planning, above all the scheduling of pavers. The system makes it possible to precisely plan the amount of material required as well as the cycles of material deliveries to the job site.

- WITOS Paving enhances process stability, cuts operating costs and leads to a sustained improvement in pavement quality.

- The just-in-time principle supports non-stop paving and prevents the mix cooling in the feed lorries as a result of prolonged waiting times.

- The networking of all parties involved in the project reveals any deviations of the operations on site from the plan so that immediate remedial measures can be taken.

- The inclusion of machine data, such as pave width and pave speed, as well as the integration of the VÖGELE RoadScan system for temperature measurement of the freshly paved asphalt make the construction process transparent and suitable for analysis.

- The analysis and documentation of operations with the help of WITOS Paving are quality assurance tools. They efficiently support the detection of faults and lead to a sustained improvement in the construction process.

Fully integrated system solution from the machine manufacturer

WITOS Paving is a unique solution from VÖGELE, the machine manufacturer, a long-standing reliable partner of the road construction industry. The paver specialist’s profound applications know-how and the worldwide service and consulting network of the WIRTGEN GROUP give customers maximum security and reliability — and on a long-term basis, too.

Advantages of a fully integrated system solution

- Full integration of the WITOS Paving system into the machine provides high functional security.

- As manufacturer of the machine technology, VÖGELE ensure that all relevant machine and paving data (such as pave width and pave speed) are connected through WITOS Paving. As a result, key parameters are available for precise planning and indication of the project’s progress.

- Since the paver’s operating status (paving, relocation on the job site, transport, neutral) is always recorded, WITOS Paving is able to carry out an extensive process analysis, thus collecting vital information for potential improvement.

- Integrating WITOS Paving into the paver operator‘s ErgoPlus console ensures that the paver operator is directly included in the system. He receives up-to-date information on the arrival of mix lorries and the progress on site.

- With WITOS Paving, our customers are optimally organized. They have the entire service and consulting competence of the WIRTGEN GROUP at their disposal.

WITOS Paving − New perspectives for asphalt paving

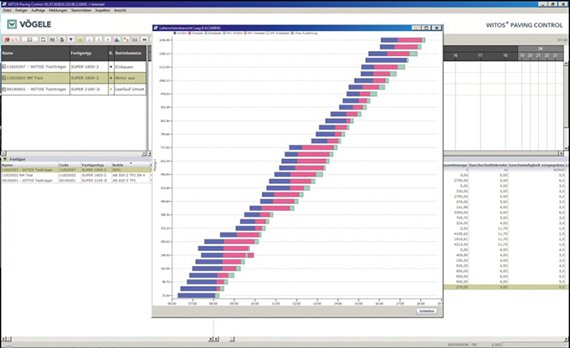

WITOS Paving Control

The planning and control module

The planning and control module makes it possible to plan projects conveniently with the aid of an assistant. The assistant guides the user through the planning process.

All key points are collected — from selection of a mixing plant out of the master data base through paving parameters, such as pave width and pave speed etc., to determination of the required machinery including availability in terms of time and material quantity.

The planning and control module is an important source of information for the site manager. With this module he can — in real time — monitor the project’s progress and call up status information referring to material delivery. Moreover, information on the paver’s operating status is available to the site manager at all times and helps him monitor and analyse the current construction job.

|

|

|

With the WITOS Paving Control module, even the temperature of the freshly paved asphalt can be displayed and monitored in real time. All in all, the planning and control module ensures perfectly cycled on-site operations and optimizes time and materials planning according to the just-in-time principle.

|

|

In addition to easy planning, WITOS Paving Control also offers a documentation function for ongoing job site operations. The supply chain, for example, can be checked at any time. |

The highlights of the planning and control module

- Clear and detailed representation of the construction project in real time

- Easy machine scheduling avoids double assignment

- Job site planning is submitted to a plausibility check

- Information on the operating status of the paver

- Coordination and exchange of data with the mixing plant

- Calculation of the number of mix lorries required

- Indication of the project progress, can be considered for future jobs

- Display of the freshly paved asphalt’s temperature measured by the VÖGELE RoadScan system

WITOS Paving Materials

The mixing plant module

The number of mix lorries calculated by the planning and control module is linked with relevant data from the mixing plant. This information serves as a basis for calculating the mix lorry cycles and arrival times of material deliveries on the job site.

In this way, paving and compacting operations as well as material deliveries can be optimally coordinated. The objective is to boost performance with precise daily planning and daily management.

The highlights of the mixing plant module

- Indication of the actual material requirement to prevent excess production and surplus material

- More uniform utilization of the mixing plant capacity throughout the working day

- Just-in-time delivery of material to the job site by the mixing plant due to dynamically updated cycles for mix lorry departures

- Easier communication between the mixing plant and the job site, particularly in the event of deviations from the plan

- Information on material deliveries to the job site (quantities in tonnes) transferred to the mixing plant supervisor

- Continuous display of the project’s progress on site

- Reduced number of mix lorries required for deliveries “free on site”

- Immediate information provided to the mixing plant supervisor in case a delivery is rejected due to poor material quality

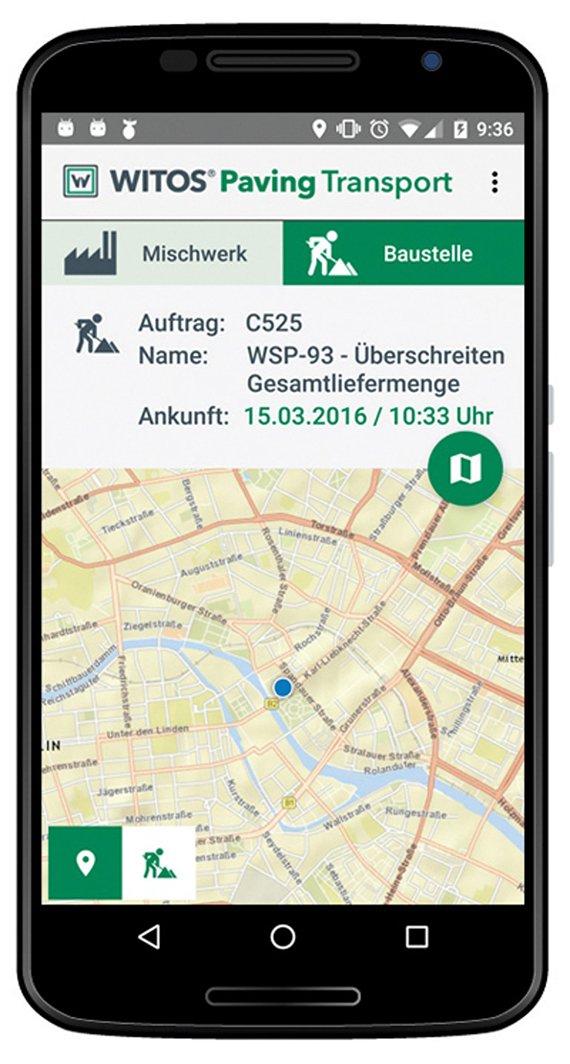

WITOS Paving Transport

The transport module

Thanks to WITOS Paving, the paving team, site manager and mixing plant receive up-to-the-minute real-time information on the arrival of mix lorries at the job site, throughout the construction period. As a result, construction projects can be handled much more reliably and in better quality than has been the case so far. This precise planning also improves the paving quality, as waiting times for mix lorries are avoided, thus preventing cooling of the paving material.

The transport module, furthermore, guarantees economic use of the mix lorries. An Android app for the lorry drivers provides important details relating to the job, such as scheduled arrival times, and regularly sends the lorries’ GPS positions to WITOS Paving. A map visualises the precise locations of both the job site and the mixing plant.

As a result, the system can continuously update the estimated time of arrival (ETA) and supplies reliable information to all parties involved in the project. |

|

|

The highlights of the transport module

- Supports the economic use of mix lorries supplying asphalt to the job site

- Informs all parties involved in the process about the arrival times of mix lorries

- An app available for standard smartphones (Android) provides maximum flexibility for the logistics company

- The driver of the mix lorry sees a map showing the location of the mixing plant and the job site via the app

WITOS Paving JobSite

The job site module

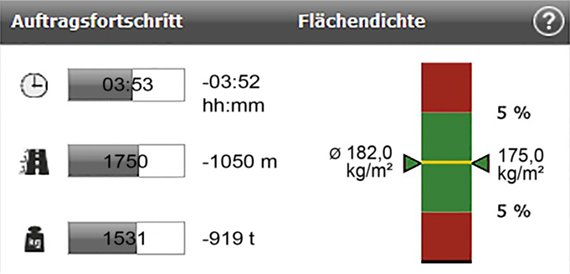

The job site module is the pacemaker of WITOS Paving. It gives the paving foreman and site manager full transparency on the project, ensuring efficient process management throughout the construction period.

The job site module delivers important real-time information on the project’s progress on site, paving performance and number of mix lorries.

| Together with indication of the planned and actual values for paving time, paved distance and quantity of paved material, this permits direct detection of deviations from the plan, such as higher material consumption. As a result, continuous paving is assured. |

|

|

The job site module allows delivery notes to be entered at the push of a button. If bar codes are used, they can be entered into the system quickly and conveniently by means of a handheld scanner.

The practical module for the paving foreman

|

The project’s progress

Extensive information is available to the paving foreman. He can view a real-time comparison of the planned and completed paving time. The paved distance and amount of material placed can also be displayed in comparison to the planned figures.

|

|

|

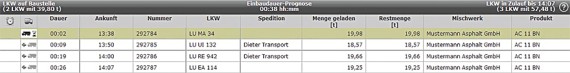

Supply chain

The job site module is a smart tool for entering material deliveries into the system at the push of a button. This information is then made available in real time to all parties involved in the project. The module also provides a convenient overview of all mix lorries, whether they are approaching or have already arrived at the job site.

WITOS Paving JobSite for the paver operator

WITOS Paving JobSite is an integral part of the VÖGELE ErgoPlus operating concept and offers the paver operator a unique tool for control and process optimization.

External equipment and staff are no longer required to perform vital functions. These can easily be done by the paver operator. This includes the recording of material deliveries.

|

|

At the same time, the job site module provides the operator with important information, for example, about the project’s progress in terms of paving time, paved distance, quantity of material placed or temperature of the freshly paved mix. |

In addition, WITOS Paving features many other functions. The places where drill cores have been taken, for instance, can be saved via the ErgoPlus display screen for later documentation and analysis.

| As WITOS Paving is connected with the ErgoPlus operating concept, the paver operator can use many functions via the system. He receives current information on the job site and the progress of the project. Thanks to clearly arranged and easily comprehensible diagrams, he can immediately recognize a deviation of the actual situation from the plan. |

|

|

The paver operator can, for instance, monitor the temperature of the freshly paved asphalt on a high-resolution display screen in real time. This offers an important control function, contributing substantially to quality assurance for the paving process.

|

|

Indication of relevant job site data

Type of material, quantity of material, length of the construction job or planned pave speed — all vital information relating to the current project is clearly displayed to the paver operator.

|

|

|

Controlling the project progress

On the ErgoPlus display screen, the paver operator can constantly monitor the completed paving time, the paved distance and the project’s overall progress. Moreover, he is promptly updated to the planned material quantity, the amount already paved and the volume still to be placed.

|

|

|

Monitoring the supply chain

The number of mix lorries approaching the job site and their material loads are also displayed. The paver operator can accept the material delivery via his ErgoPlus console, entering it into the WITOS Paving system.

|

Temperature measurement with the VÖGELE RoadScan system

One of the crucial criteria for high-quality asphalt paving is the temperature at which the material is paved and compacted. Clients are therefore increasingly demanding documentation showing the temperature of the freshly paved asphalt. The non-contacting temperature measurement system is an integral part of WITOS Paving and can be used on all VÖGELE pavers equipped with a paver operator’s ErgoPlus console with colour display.

The highlights of the VÖGELE RoadScan system

- Area-wide temperature measurement across the entire pave width of up to 10m

- Real-time display on the paver operator‘s ErgoPlus console to help the paving team achieve a high-quality asphalt pavement

- Simple mounting of the measuring unit without any adjustment (Plug & Play)

- Reliable technology thanks to a robust design with no moving parts

The highlights of the job site module

- Total transparency of the construction job for paving foreman and site manager

- Display of vital information on the paver operator’s ErgoPlus console

- Information on currently delivered material quantity and current delivery situation

- Display of planned and actual values for paving time, paved distance and quantity of paved material

- Simple entering of delivery notes

- Smart “outstanding quantity” calculator automatically determines the quantity of material still required for the job

- Noting down of ad-hoc orders directly on the job site

- Real-time updating of the project’s progress on site. If a data link is not available, the delivered material can also be conveniently recorded in offline mode.

- Early detection of plan deviations and prompt initiation of remedial measures

WITOS Paving Analysis

The analysis and documentation module

The WITOS Paving analysis, statistics and documentation tool permits objective assessment of a construction project. Easily understandable and clearly arranged diagrams and charts enable the site manager or planning engineer to draw important conclusions from a completed construction project.

- Where did which lorry unload material?

- What was the pave speed?

- Where did the paver wait?

- How many mix lorries were on the job site?

- How long were the waiting times and can the number of mix lorries be reduced?

- What costs were caused by waiting times?

WITOS Paving Analysis provides the answers to all these questions. The findings gained here permit continuous optimization of future projects.

In addition, the WITOS Paving Analysis module allows for a detailed documentation of the entire process chain — from asphalt production through to paving.

The highlights of the analysis module

- Objective assessment of construction jobs based on informative diagrams and analyses

- Documentation of empirical values, promoting a “Best Practice” approach

- Examination of interruptions in paving to identify possible optimization measures and ensure continuous improvement

- Assessment of the paver’s operating efficiency (standstill periods versus productive periods)

- Precise documentation as proof of quality (when using the RoadScan system for asphalt temperature measurements)

- Data export as CSV or PDF files for further use in other programs

Công nghệ khác

VÖGELE Get the Job Done Accurate to the Millimetre

“AutoSet Plus” is Quality Assurance at the Press of a Button

SprayJet versus Conventional Paving with Pre-Spraying of Emulsion